About Kelsall 39 Sailing

This about page is to give you an introduction to what Kelsall 39 sailing is about, and what makes it such a cool project.

Firstly, we are here to get everybody out on the water and sailing!

That’s it, everybody! No need to pay, no need to work, no need to worry! Just come sailing and have fun, and be happy, and lets see where the wind takes us.

Really, that’s it. Don’t believe me? Well then – get in touch and see what we can organise!

Hope to see you on board soon =)

Sailing West

About the boat

This rest of this page contains a relatively detailed introduction to this particular Kelsall 39. I also include points of interest and discussion concerning aspects of the vessel. I can’t hope to cover everything here so please if you find that you have any questions please contact me directly.

1. A brief history

This trimaran, called “Altergo” is built from plans drawn up by Derek Kelsall. Kelsall is famous for his multihull designs and are still being built.

Altergo was launched in 1976 to compete in the single handed transatlantic race known as the OSTAR. There is a lot of information about the races to be found at the organiser’s web site: Royal Western Yacht Club and specifically the OSTAR 1976.

This particular Kelsall 39 was built buy a gentleman by the name Chris Ward at Emsworth on Chichester Harbour on the South coast of England, at a small yard which is now called Multihull World.

Her original hull colour was red, reflecting the sponsor’s colours. Subsequently that was changed to cream when the sponsor changed their colour scheme. The original sail number was 122, issued for the OSTAR.

Altergo in the 1970’s

The design is quite successful as there have been 8 Kelsall 39’s built over the years. Of these 8, I have I have seen or heard about 6 of them personally and in use. A very nice example is Aqua Blue which is mostly sailed in the Mediterranean.

Altergo made the start of the great 1976 OSTAR and by account I’ve heard was doing quite well in the multihull class. Unfortunately some 4 days after the start Mr. Ward suffered loss of steering when Altergo’s rudder quadrant failed. Mr. Ward had to return to England – maneuvering the boat wit the emergency tiller when needing to tack, but generally keeping the boat on a heading with sail trim and use of the especially the cockpit dagger board.

Multihull development in the 70’s and 80’s was exploding, and enormous progress was made in leaps and bounds. For Altergo there has been no more attempts at crossing the Atlantic in a race. The boat was based in Chichester for a while, and apparently used for leisure cruising. The boat was then stolen from the Medway River in Kent in England, and later recovered near Stockholm in Sweden. The thief was jailed in the UK after serving a term in Sweden for another theft. The thief had painted the boat blue to disguise its identity.

In 1991 the current owner purchased the boat. Altergo was used as a family cruising boat with multiple trips in the Baltic from her base in Karlsham in the South of Sweden.

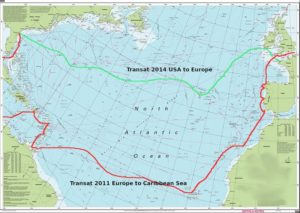

In 2011, after a complete new-build of the two lateral-resistance fins, and the changing of all bulkheads supporting chain-plates Altergo set off to England. Later that year she sailed to the Canary islands and across the Atlantic. Two years were spent sailing the Caribbean, as far as Colombia and Panama, but also Florida in the United States.

In May and June 2014 the return trip across the Atlantic was made. There is an article about that transatlantic passage to be found on this website here. Altergo returned to Karlshamn in August 2014.

Since 2014 Altergo has been launched every year and is sailed in the Baltic sea.

2. Build method – hulls

The construction method is hand-laid fiberglass roving on a special closed-cell foam core under the brand Airex. The resin used is polyester. Construction is according to instructions drawn up by Derek Kelsall.

From sources which I trust I have confirmation that it is an excellent build method in terms of durability, strength and weight. Personally I have seen no evidence of de-lamination from the foam core on Altergo.

Bulkheads are marine plywood and covered with fiberglass mat. The resin does not adhere to plywood as well as to foam core. However the method of encapsulation ensures rigidity anyway, and thus maintains the properties required for structural integrity.

The boat has been built with 11 water-tight compartments. The main hull has a crash box in the front. The fore peak and aft-cabin are separate from the main saloon. The outer hulls are both divided into three watertight compartments. Finally the compartment under the cockpit can be made separate from the rest of the boat.

Under the saloon floor there are two very large water-tanks of total more than 600 liter capacity – I think built with the idea in mind of making a non-stop around the world passage.

3. Build methods – arms

The arms which span the breadth of the boat are built in place. It is easiest to describe them as being 4 in number. Two in the front, one above the other, and the same for the aft.

The top arms are thick-walled aluminium extrude which is probably quite heavy but certainly very strong. The lower arms are fiberglass, unidirectional roving, and again, extremely solid.

The span between the main hull and the floats is short because of the “cheeks” on the main hull. This is obviously again adding to strength and rigidity. The whole construction has never shown any signs of fatigue or weakness.

4. Mast and standing rigging

Another interesting aspect to this particular Kelsall 39 is her mast. It is often said that half the value of a performance sailing boat is the mast.

The mast on Altergo was built for Herbert “Blondie” Hasler’s experimental monohull “Sumner” (that boat is in Bordeaux currently, but it is hard to find information on it). The mast had some adaptations made, mostly the addition of extra shrouds, for stepping on a multi-hull. The builder is Proctor Spars ltd.

The engineering and manufacture of the mast and it’s fittings is frankly aircraft grade and for its time it was cutting edge. There are innovations such as internal mast sliders, but in combination with a bolt rope groove. It means the sail can be slab reefed with the benefits of staying secured on the luff just like is very normal, but in addition also having the benefits of sail trim, strength and minimal drag of bolt-rope.

Another innovation was on-boom furling for reefing the mainsail. That is not the current system, and instead full-length battens, lazy-jacks and slab-reefing are used.

The mast is tapered at the top for weight reduction. Again a sign of it’s no-costs-spared origins.

The rig is a Bermudan sloop. There are double spreaders, with the top set angled forwards to avoid the necessity of running back-stays to support the mast at the forestay tang – which is at 3/4 of the height of the mast.

Unusual is the twin head-stays, next to each other, for rapid sail changes. Or as we used it – a safe and simple trade-wind double head-sail set up!

Also fitted on the mast are twin tracks for spinnaker poles. The tracks allow the aft end of the pole to be raised up and the pole gybed by passing inside the forestay without disconnecting from the mast. Spinnaker halyards are to the masthead.

We have rarely used the spinnaker poles as the width of the boat allows the spinnaker guy to be led to strong points directly on the hull… or simply a cruising-chute/asymmetric spinnaker.

Originally the main halyard was a captive wire halyard – changed to modern fiber halyard and a self-tailing winch. For the headsails there were originally turning blocks at the foot of the mast leading to a pair of winches on a pedestal in front of the mast. Now the system is one halyard led aft to a winch in the cockpit and the second halyard to a winch on the mast.

Finally the steps on the mast were added with the mast in situ. They have proved very useful on many occasions.

5. Deck

As opposed to many trimarans Altergo has rigid decks between the main hull and floats. This is a compromise between the lighter netting, and the structural performance laterally and in twist for rigid decks.

As a side note; the rigid deck is much more durable than a netting, requiring only fresh paint to be brought up to scratch.

The deck is all constructed using the same foam core as the hulls. Water ingress, core-rot and all associated problems of wood-sandwich construction is a non-issue when using foam.

6. Engine and propulsion under power

The auxiliary engine was originally a 25HP 2-stroke long shaft (20 inches). There is a well in the cockpit which facilitates the folding up of the engine. There is a hatch which then closes the cut-out in the hull.

The system is excellent for sailing performance. For motoring it is less ideal – if only because the cut-out is off-centre and hence if the boat is heeling the wrong way the engine does not stay deep enough in the water to effectively work.

Motoring is not particularly effective in choppy waves either. Many possibilities exist to improve the auxiliary propulsion system – most attractive is conversion to electric.

7. Steering system

The steering set up is a wheel helm in the center cockpit. In event of steering failure there is an emergency tiller which fits directly on the rudder stock.

The boat can self track on any point of wind between close-hauled and on a reach, as is the case with most sloops.

A benefit with the multi-hull is that there is the possibility to self steer down wind as well, something rarely possible with a mono-hull. Dead down-wind and approximately at 135 degrees of true wind angle are possible to balance the boat. Certain sacrifice to speed has to be made to achieve this however.

We had no autopilot or wind-vane self-steering for either of the transatlantic passages. I can say – after sailing the boat once around the Atlantic – that time spent with someone helming is less than 50%. According to Mr. Ward he had a Gunning pendulum-servo wind vane gear installed for the OSTAR, which worked very well, but also points out that the boat could often be balanced and sailing very well once the correct sail trim and the dagger-board position was set.

8. Comfort

Comfort on board is good. There is ample headroom, and the main cabin feels spacious.

There are excellent sea-births: one to port and one to starboard. The saloon table, which seats 8 people, can be lowered down creating a big double bunk. Usually the aft-cabin is comfortable enough as it has a permanently installed double bunk.

The galley is along the port side of the saloon. It is perhaps the less attractive part of the interior, and could be built to make more effective use of the space available.

Refrigeration, water on tap, and an oven are luxuries not found on this trimaran, the fact is that there is not shortage of space to fit them. For us the salt water tap and large sink, together with a three-burner gas stove has been sufficient.

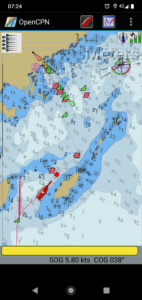

As for the navigation table, it is to starboard in the main saloon. It is a full size chart table, which is nice, but with today’s electronics less important. So, again, more could be done to better use the space.

The fore-peak is only accessible from on deck but provides ample space for ground tackle and sails. An idea would be to create a double bunk in the fore-peak. Access could be made through the waterproof bulkhead to the saloon.

Often people ask if there is any accommodation in the outer hulls – but they are in fact completely empty. We have always used it as storage space for windsurf mast, oars and paddles, fishing rods and the likes.

There is a large heads/bathroom. It is a manual pump out. There is the possibility of fitting a holding tank. A shower could also be installed but is not currently either.

As an example we we’re 6 people on board for the crossing from the Canary islands to Tobago in the Caribbean.

9. Performance

The average daily run for the boat in all our offshore sailing was 150 miles, with a record run of 280 miles.

The benefits of multi-hulls and their ability to create apparent wind is true for Altergo as well. It is very satisfying in light winds to have steady drawing sails and good forward motion. The same breeze sees mono-hulls rolling in the waves and their sails flapping – achieving absolutely nothing.

The motion when sailing is very good on most points of wind. Beating to windward is not a favourite when on any kind of multi-hull – the same holds true for Altergo.

Down wind in normal conditions the boat is so steady one rarely seeks a hand-hold, and a cup of tea will stay put on the table quite easily.

The lateral resistance is provided by a fin on each outer hull. It works, but as with most old multihulls close hauled performance is mediocre. A more complicated but a slightly better performing system for providing lateral resistance is a dagger-board. Obviously Altergo could be converted to that easily enough, but the trade-off is all the space lost in the main saloon.

I recommend keeping the boat light. The greatest difference when the boat is light is the ease of helming. With 6 people on board, and food and water for a month at sea, Altergo still sailed well, but was heavier to helm in following seas.

According to Mr. Ward who built the boat she could set a very good pace when lightly laden. During the initial sea-trials she would make 14 knots in 20 knots of wind while reaching. If the weight is increased then the performance is more in the region of 9 to 10 knots.

10. Mooring and anchoring:

With the interest of keeping the boat light there has never been an electric windlass installed. The chain is simply pulled up over the bow-roller and dropped directly down the hatch to the fore-peak.

Mooring in harbour is easy with 2 cleats on the main hull aft, fore and aft cleats on the two outer hulls and finally a main cleat forward on the main hull with fair-leads. Lifelines or stanchion bases on the outer hulls are strong points for securing fenders.

11. Specifications

Length over all: 11.9m (39ft)

Width: 6.7m

Draft: 0.75m (A little more when sailing)

Weight including mast, engine, ground tackle and sails: 3650kg

Rigging and sails specifications (lengths in centimeters):

Mainsail triangle

Luff: 1340

Foot: 370

Fore triangle

Luff: 1139

Foot: 424

Reacher

Luff: 984

Leech: 834

Foot: 650

Area: 26.85 sqm

Not currently built

Dacron 8 Oz per sq yard or 270grams per sqm. Maybe a little lighter.

Solent #1

Luff: 1090

Leech: 980

Foot: 465

LP: 450

Area: 23.0 sqm

Solent #2

Luff: 1008

Leech: 873

Foot: 411

LP: 313

Area: 17.8 sqm

Jib #1

Luff: 6.73m

Foot: 4.16m

Leech: 5.48m

LP: 3.36m

Area: 11.39sqm (3 sides)

Jib #2

Dimensions currently not known

Jib #3

Dimensions currently not known

Spinnaker

Dimensions not currently known

All dyneema halyards

2 primary winches in cockpit Lewmar 46 standard.

1 winch at cockpit Lewmar 28 standard

2 winches on mast. 1 self tailing.

Well working round tackle:

Anchor #1: CQR 25kg (this is actually a little over the required)

Chain #1: 25m – 8mm

Anchor #2: Danforth 14kg (suitable length of chain aboard)