We arrived to Ferragudo in the beginning of April. The plan was to make a short break and leave the boat in a safe place for a few weeks. The reason was work which I had to do on another boat. These few weeks turned into a month, then another month, and here we are in July and Kelsall is still here! I have been back three times during the period, but only for 4 or 5 days at a time – not enough to sail anywhere, but instead I have been working on the boat.

The job which I have really wanted to get done since a long time is to make a good and thorough job of the deck area and the paint system on it. This old boat has had her decks painted probably 20 times over the years, and the build-up of paint, as well as the original polyester filler meant that the paint job would never look good for very long. The nice new paint job would always get little cracks in it, as the deck heats up in the sun and cools off at night. Especially in Sweden when the wintertime sees sub-zero temperatures during the night, and then frequently thaws during the day – a winter like that and I’d get back to the boat in spring to see a horrible, dirty and cracked surface finish.

The solution I have chosen to the problem is to make a complete new surface, but instead of just using paint I decided to take away all the paint and old polyester filler, and start fresh with modern epoxy microbaloon fairing compound. Once happy that the surface is flat enough the whole surface is to be covered with a light fibreglass fabric and epoxy resin. The fibres will bind the surface, so that even with the changing temperature and exposure to the elements there should be no cracks appearing.

This is a huge job! The deck surface area that I am doing (and it is not all of the deck) is 34 square meters. It’s not only the 40 hours of work required to remove all the old paint and filler (this is now finished!), but then new fairing and filling (which is also finished!), but then just the cutting and laminating is going to take lots of hard work too! Once all the decks have this fibreglass cloth on them, then a little more epoxy filler will be needed to smooth the traces of fibres, and especially the joins between the strips of glassfibre. After that is the paint primer, then the topcoat, and finally the anti-slip surfaces.

I think that once done it will look amazing. It will be extremely durable, and it will also be lighter than the old layers and layers of paint. I’m excited! Actually, a few of the sail control systems, and the lifelines, and some other deck fittings are all being modified now as well. I have removed the system of tracks for controlling the sheeting points for the headsails, and instead gone to the much lighter and more effective system of friction rings and rope control systems. Yes, there’s lots going on, all of it saving weight, getting stronger, being more clean, and being more effective. I’m excited!

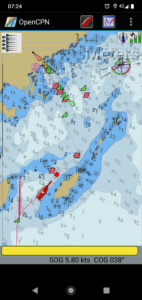

I should probably get outside and start measuring and cutting the glassfibre now… there’s no time to be lost! My hope is to get the most important parts of the deck done in the next few days, but be ready to sail if the weather looks good for it. I would like to be in Lisbon with the boat for the 21st July… so that gives me a little time.

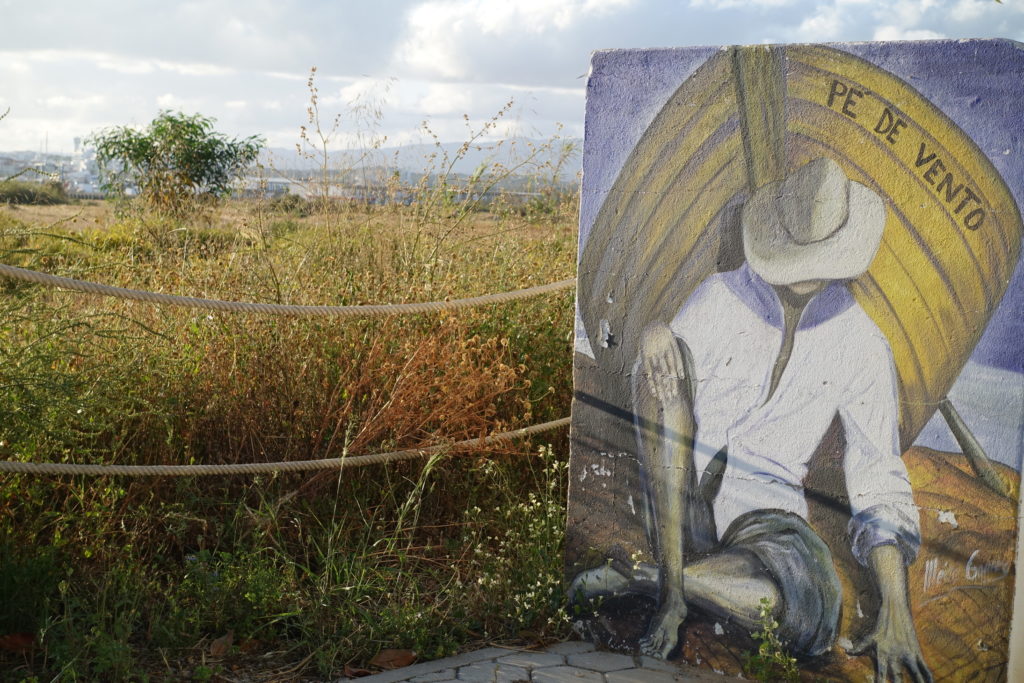

Lastly, here’s some photos of the deck after grinding and then filling with epoxy, and some pictures of the town of Ferragudo, near Portimão in Portugal where I am doing the work.